As one of Eaglestone’s newer engineers, Bill Z. has proven to be a driven and talented asset to his team, as well as an ambitious and creative co-worker. Bill’s team-first mentality has helped him find a seamless fit among his peers at Eaglestone over the last two years. From asking and answering project questions to […]

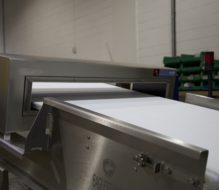

The TrackIQ Sorting Conveyor™. Ready for business.

What does it take to get a room full of Eaglestone engineers excited? Try the launch of a mind-blowing new piece of equipment like the TrackIQ Sorting Conveyor™. It could be our smartest and best innovation yet. We designed the TrackIQ at the request of several smaller and mid-size clients. They wanted access to the […]

Eaglestone Serves Up Their Skills at IBIE

The International Baking Industry Exposition (IBIE) is an exciting tradeshow that only comes around once every three years. When it does, it brings the industry together to get a first-hand look at the newest and most exciting advancements. The technology displayed there helps shape the future of the baking industry. This year, we traveled to […]

See the Future of Your Operation with the 3D Faro Laser Scanner

Whether you’re starting from scratch or just looking to make some upgrades to your current set-up, being able to see the final result before any work starts creates a huge advantage. Our 3D Faro Laser Scanner takes all of the guess work out of the design process and allows you to see the full picture […]

Say Hello to the 4000 Series Chicane Conveyor System

The 4000 Series Chicane Conveyor System is a notable segment of the Eaglestone lineup of packaging conveyors, and it’s perfect for bringing order to sometimes chaotic mass flow production. Whether products have been grouped together deliberately or as an unintended result of other parts of your process, this system quickly organizes products into neat rows […]

Jesus Vega: A Cut Above

After years of working in landscaping, Jesus Vega was sent to us by a temp agency to help out in our Sawing Department. Recognizing a hard worker when we see one, we offered him a full-time job. Jesus was ready for a change and jumped at the chance to leave landscaping behind. It’s hard to […]

Conveyor Consultants: Your Key to Excellence and Value

When facing a challenge that requires specialized knowledge and expertise, most of us turn to professionals. From auto mechanics and tax consultants to doctors and lawyers, these experts can save your time and money, not to mention helping you get the outcome you were looking for. For the same reasons, it makes a lot of […]

Integrating Metal Detector Heads: What You Need to Know

It’s a simple fact. Metal does not belong in food items. No matter how it might find its way there, it must be found and removed before it reaches the consumer. Meat, poultry and vegetable processors, in particular, depend on metal detectors to keep food safe. In fact, it’s a requirement. If you are starting […]

Cryogenic Tunnel Freezer Video

The modular design of the Series 808 Cryogenic Tunnel Freezer employs automated top lifts and an open interior frame for easy maintenance and cleaning. Integrated fans assist in maintaining temperatures for consistent heating/cooling rates to assure a quality product. Additional features include: -Expanding seals to eliminate loss of tunnel temperatures -Tumbling option for more thorough […]

Mark Villanueva Found His Dream Job in the Machine Shop

Fabrication wasn’t the first thing on Mark Villanueva’s career checklist. In fact, he didn’t even have a clue what a CNC machine was until he left his bank job nine years ago and joined us as a water jet operator. His plans to learn medical billing and coding were quickly forgotten as he visited the […]