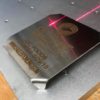

Eaglestone’s Flex-Scraper (Sanitary Food Grade Belt Scraper) is the key to a clean belt and sanitary processing line. Not only will you get the job done quicker, the process will be more efficient and sanitary the whole way through. Our engineers are proud to reveal the latest in Eaglestone innovation—the Flex-Scraper with a unique design […]