Mistracking and rubbing against the frame causes belts to fray at the edges, and that’s only the beginning. Pieces of the belt material can shear off at the friction point and be introduced into the food products being transported. Before you know it, the whole line is down for the unscheduled replacement of a ruined belt.

Mistracking and rubbing against the frame causes belts to fray at the edges, and that’s only the beginning. Pieces of the belt material can shear off at the friction point and be introduced into the food products being transported. Before you know it, the whole line is down for the unscheduled replacement of a ruined belt.

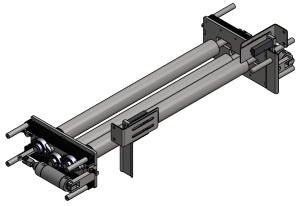

The Eaglestone Accu-Track 3 Conveyor Belt Tracking System was designed specifically to keep belt mistracking from decreasing productivity. Its automatic monitoring and adjustment capabilities keep your processing line operating at high levels of performance.

Speed and Accuracy

The Accu-Track 3 provides superior belt control the length and width of the conveyor with a complete line of built-in features to minimize lateral belt movement. These include full range belt edge tracking, micro-adjustable belt edge guides and continuous belt location monitoring. A Dual Cylinder/Dual Sensor configuration delivers accurate belt tracking automatically via high belt tracking force. Pneumatic cylinder action provides amazingly fast response times.

Reduced Down Time

You can get the most lifetime usage out of your belts and save money on maintenance and installation as well. Retrofits are quick and easy thanks to the Accu-Track’s integrated design. Scheduled maintenance is reduced through the use of stainless steel rollers with sealed cartridge bearings and solid thermoplastic (nylon) tracks that don’t require lubrication.

Of course, safety should never take a back seat to speed, so the Accu-Track 3 is designed with formed stainless steel guards that fully enclose tracking units to ensure operator safety.

The Bottom Line

Eaglestone’s engineers have the industry knowledge and experience to recommend the right conveyor belt tracker system for your needs. They can identify the optimal location on your current conveyor and effectively retrofit your problematic conveyor to deliver years of trouble-and worry-free automatic belt tracking. Let us review your operation and determine if the Accu-Track 3 Conveyor Belt Tracking System is right for your plant. The competitive advantages for you include:

- Increased productivity and throughput

- Extended usable belt life

- Reduced overall cost of belt ownership

- Decreased costs for adjustment of fixed tracking components

- Reduced unscheduled downtime

- Improved product quality and flow

- Decreased product loss from frayed belt contamination

- Reduced unscheduled sanitation costs

… [Trackback]

[…] There you will find 48641 additional Info to that Topic: eaglestone.net/2015/11/accu-track-3-keeping-belts-and-productivity-on-track/ […]

… [Trackback]

[…] Here you can find 96892 more Info to that Topic: eaglestone.net/2015/11/accu-track-3-keeping-belts-and-productivity-on-track/ […]

… [Trackback]

[…] Read More here on that Topic: eaglestone.net/2015/11/accu-track-3-keeping-belts-and-productivity-on-track/ […]

… [Trackback]

[…] Find More on on that Topic: eaglestone.net/2015/11/accu-track-3-keeping-belts-and-productivity-on-track/ […]